utility washing

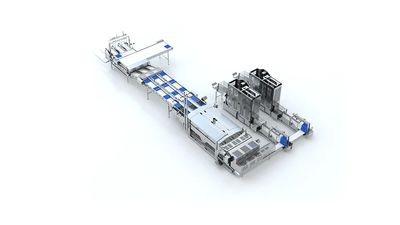

Tray Washer - Off-line STW-2/3

capacity

The STW 2 can process up to 6,500 trays per hour. The STW 3 can process up to 10,000 trays per hour.

user friendly

The tray washer can be purchased without the need of an OptiLoader as the washer can be operated on its own. The tray washer is automated and therefore requires little attention.

durable

Made of stainless steel the tray washer is hard-waring. The tray washer uses a destacker infeed which can be adjusted for the type of tray that you have. Up to 264 nozzles clean the trays and then the trays are spun dry.

Optional

Installation options for the tray washer:

>Choose the direction in which you need your conveyor to face.

>Add steam heating or electrical heating.

>Add a sanitiser spraybar for added sanitization.

>Add automatic tray loading.

> Add CIP cleaning.

>Add a separate washer module for after rinsing.

For more information please use the contact form at the end of the page.

training

Training is provided with installation of the tray washer.

Tray Washer - In-line STW-12/18

capacity

The STW 12 can process up to 5,000 trays per hour. The STW 18 can process up to 7,200 trays per hour.

user friendly

The tray washer can be purchased to be used with the OptiLoader Plus 12 and 18, with the trays being washed after they are empty with stuck eggs in trays not being washed. The tray washer is automated and therefore requires little attention.

durable

Made of stainless steel the tray washer is hard-waring. The tray washer uses a destacker infeed which can be adjusted for the type of tray that you have. Up to 264 nozzles clean the trays and then the trays are spun dry. The tray washer is energy cost saving by using water from collection tanks.

Optional

Installation options for the tray washer:

>Choose the direction in which you need your conveyor to face.

>Add steam heating or electrical heating.

>Add a sanitiser spraybar for added sanitization.

>Add automatic tray loading.

> Add CIP cleaning.

>Add a separate washer module for after rinsing.

For more information please use the contact form at the end of the page.

Layout

A free layout drawing is provided of the machine.

Tray Washer - Combi In-line/Off-line STW6-1

capacity

The STW6-1 can process up to 6,000 trays per hour.

user friendly

The tray washer is automated and therefore requires little attention, with the washer being able to be used inline and offline.

durable

Made of stainless steel the tray washer is hard-waring. The tray washer uses a destacker infeed which can be adjusted for the type of tray that you have. Up to 264 nozzles clean the trays and then the trays are spun dry. The tray washer is energy cost saving by using water from collection tanks.

Optional

Installation options for the tray washer:

>Choose the direction in which you need your conveyor to face.

>Add steam heating or electrical heating.

>Add a sanitiser spraybar for added sanitization.

>Add automatic tray loading.

> Add CIP cleaning.

>Add a separate washer module for after rinsing.

For more information please use the contact form at the end of the page.

training

Training is provided with installation of the tray washer.

Pallet Washer

user friendly

The pallet washer is automated and therefore requires little attention. The pallet washer can be used fully automated, or manually loaded and unloaded.

durable

Made of stainless steel the pallet washer is hard-waring.

Optional

Installation options for the pallet washer:

>Heavy-duty execution for cold water washing.

>Automatic clean pallet return.

>Extension of loading and unloading conveyors.

For more information please use the contact form at the end of the page.

training

Training is provided with installation of the pallet washer.

Contact Us

got a question?

We love to hear from you and how you're doing. Email or call us, and we will get back to you soon.

Message us on WhatsApp

4pe Systems Ltd

29 Lyth Hill Road, Bayston Hill, Shrewsbury, UK

Mob: 07801565860 Tel: 01743872732 E-mail: John@4pe.co.uk