Contact Information.

Tel: 07801565860

Email: john@4pe.co.uk

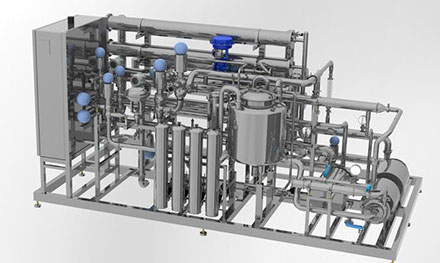

Egg white treatment

The principle of ultra filtration (UF) and reverse osmosis (RO) is a physical separation with the intention of increasing the dry matter content of the albumen prior to drying.

The extent to which dissolved solids, turbidity and microorganisms are separated is determined by the size of the pores in the membranes. Substances that are larger than the pores in the membranes are fully separated. Substances that are smaller than the pores of the membranes are partially separated, depending on the construction of a refuse layer on the membrane.

For albumen, the dry matter is increased from 10-12% up to 20-24%, thus reducing the load on the dryer to 50%, compared to direct feeding of albumen into the dryer.

The total energy consumption of the dryer is reduced significantly and/or the total plant capacity can be increased.

SANOVO offers two different systems in order to meet the needs of our customers.

ULTRA FILTRATION

In Ultra Filtration, the albumen flows towards a membrane, allowing only water and some salt and sugar to pass. The entire process requires a working pressure of as little as 5.0-6.0 bars which means low energy consumption and a smaller investment in equipment compared to reverse osmosis.

REVERSE OSMOSIS

In the reverse osmosis process, the albumen is forced towards a membrane, allowing only water to pass without any product loss. This process requires a pressure of 20-30 bars with increased requirements to pumps and pipes and, of course, higher energy consumption.

Ultra Filtration & Reverse Osmosis

The principle of ultra filtration (UF) and reverse osmosis (RO) is a physical separation with the intention of increasing the dry matter content of the albumen prior to drying.