Contact Information.

Tel: 07801565860

Email: john@4pe.co.uk

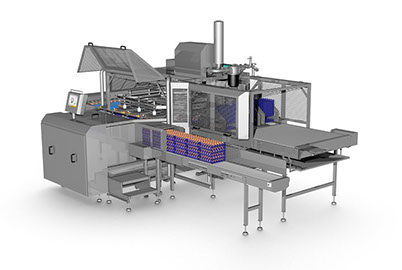

Optiloader

Handle any types of trays

Flexible egg and tray loading

The SANOVO OptiLoader concept has been optimised for handling of the 'daily' change in egg quality, tray size and shape. The SANOVO OptiLoader handles eggs from 40 to 80 grams without any loading complications. The loader handles any type of trays available on the market.

Effective modern design

Gentle in-feed and de-stacking

A gentler handling of eggs has been ensured by using electronically controlled servo gear motors with optimised acceleration and deceleration of all movements. The rotary design of the loader has made it possible to reduce process speed by 50% compared to other machinery available on the market which, together with the servo technology, makes a gentler handling of eggs compared with old-fashioned machinery.

Extremely gentle delivery

Two-step blow-back system prevents blocking

The two-step, blow-back system prevents blocking of suction heads. The eggs are gently delivered by a low vacuum reduction, followed by low pressure. After a second, the nozzles are cleaned by high pressure cleaning to prevent blocking in the vacuum system.

Extremely gentle delivery of the eggs onto the grader infeed conveyors

The OptiLoader Plus 12 C and 18 C deliver the eggs onto the roller in feed conveyor with a speed synchronised with the speed of the infeed conveyor. Hereby, the number of created checks are kept to a minimum.

Reduced manpower

CIP system cleanable

All internal parts of the SANOVO OptiLoader can be CIP cleaned automatically. Manpower and water requirements are reduced as a result of collection and recycling of CIP.

Playing It Safe

Highest Operator Safety in the Industry

The SANOVO OptiBreaker has the highest operator safety in the industry and complies fully with all regulations in the CE Directive.

All risk areas are fully capsulated by fences or doors with safety switches. All fences are incorporated into the machine design, so there will be no extra cost for separate safety fences and gates.

Empty tray stacking and stuck egg detector

In order to secure optimal output and minimal manual handling, empty trays are automatically stacked, and stuck eggs are immediately discharged to the stuck egg conveyor.